Polyethylene Wax Rau Sau Master Batch

Technical Index

| Qauv No. | Softenpoint ℃ | Viscosity CPS @ 140 ℃ | Kev nkag mus dmm @ 25 ℃ | Qhov tshwm sim |

| fwv 801 | 95-100 : kuv | ≤ 20 | ≤ 7 | Dawb Micro hlaws / pellets |

| FWM 1003 | 110-115 : kuv | 15-25 | ≤ 5 | Dawb pellet / zog |

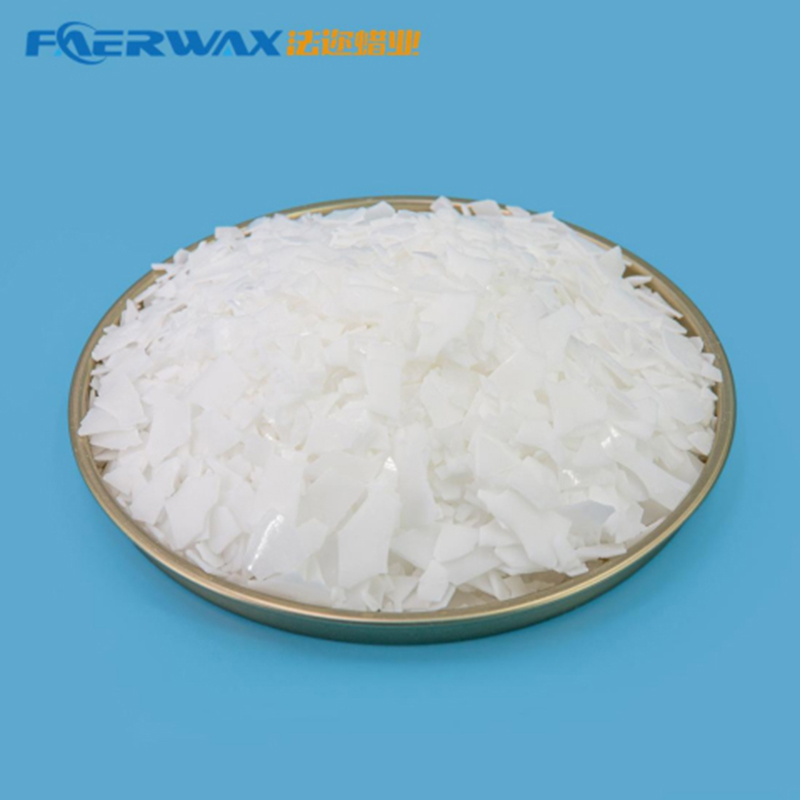

| FWM 1080 | 110-115 : kuv | 20-100 | 3-6 | Dawb flake |

| FWM 1001 | 100-105 : kuv | ≤ 20 | 3-6 | Dawb pellet |

Qhov zoo

Faer wax tuaj yeem nqa cov txiaj ntsig hauv qab no ua cov roj nplua nyeem zoo, tus neeg sawv cev dispersing thiab lub ntsej muag ci ntsa iab rau cov masterbatch puv:

1.Txo extruder tam sim no ntws thiab nce ntau lawm.

2.Increase khoom aesthetic npaum li cas thiab txhim kho lub nto gloss.

3.Txhim kho rau cov dispersion ntawm fillers, nce kev faib ua feem ntawm muab tub lim.

FAQ

1.Koj puas yog cov chaw tsim khoom lossis tuam txhab lag luam?

Peb yog cov chaw tsim khoom siv quav ciab hauv Suav teb.

2.Koj cov khoom tseem ceeb yog dab tsi?

Peb cov khoom tseem ceeb yog Polyethylene wax (PP wax), Polypropylene wax (PP wax), Fischer Tropsch wax (FT wax), Paraffin wax thiab Oxidized wax.

3.Koj lub sijhawm xa khoom ntev npaum li cas?

Feem ntau nws yuav siv sijhawm 10-20 hnub tom qab kev sib cuag tau kos npe.Nws nyob ntawm cov ncauj lus kom ntxaws thiab cov khoom.

4.Koj cov nqe lus them nqi yog dab tsi?

TT lossis LC thaum pom.

5.Qhov ntau npaum li cas rau 40'FCL?

28 Tons ib 40'FCL tsis muaj pellt thiab 24 Tons ib 40'FCL nrog pellets.

Factory Duab

Factory Rhiav

Cov khoom siv ib nrab

Ntim & Cia

Ntim:25kg / hnab, PP lossis kraft ntawv hnab